At this time, it is very important to be familiar with materials and finishes that aid in stopping the spread of germs. It’s a known fact that our hands contain a lot of germs and it’s very easy to spread them by touching anything from hard surfaces to textiles, for example.

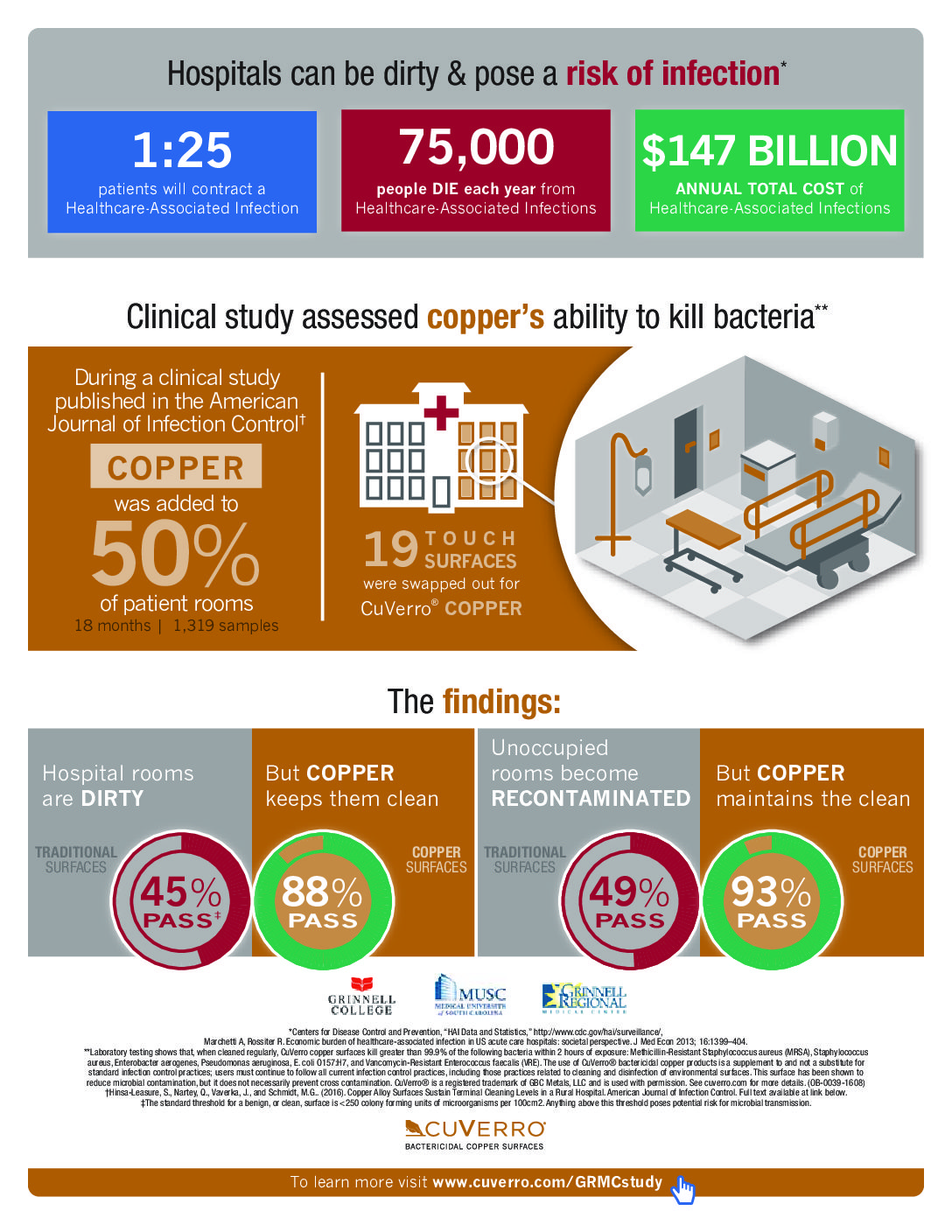

Did you know that billions of dollars are spent each year to aid in stopping the spread of infections and germs in hospitals and medical facilities?

While we know that one very important step is keeping your hands washed and sanitized. Another way to aid in the prevention of infections is by adding bacteria-fighting materials within a space. Antimicrobial materials can contribute significantly to the health and well-being of our surroundings in medical and commercial spaces.

SOLID SURFACES

Many hard materials gain their antimicrobial properties from smooth, non-porous surfaces that limit the ability of bacteria to permeate a material´s exterior. With no voids for bacteria to hide in, the surfaces of such materials can be easily cleaned of any biofilms that manage to develop.

Cristalite is composed of 85% quartz and 15% acrylic. It has a smooth surface similar to that of polished granite however it is 30 times more hygienic than granite due to its non-porous nature. Also compared to Granite, Cristalite is three times harder and is resistant to cuts and bumps, which is also very helpful in keeping out germs and bacteria.

Corian® is nonporous and hygienic. Its smooth surface does not allow liquids to penetrate and that makes it easy to clean. Bacteria and mold have nowhere to take root. When Corian® looks clean, it really is clean. To learn more, here is a presentation from Corian about why is it an ideal surface solution for today’s healthcare environement.

COPPER

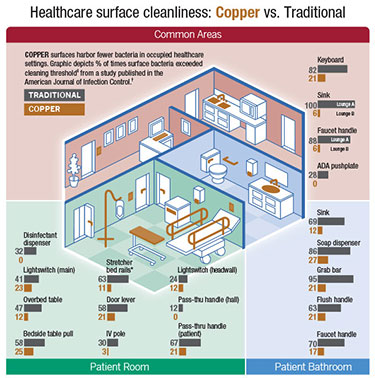

Antimicrobial properties of copper and copper alloys aid in the spread of infection and bacteria. Copper alloys have antimicrobial properties that kill microorganisms on contact and will prevent the growth of bacteria and fungi. Healthcare-acquired infections (HAIs) are on the rise in hospitals and medical facilities. It is now important to incorporate copper finishes into hospitals and medical facilities as much as possible. Studies have been done that have produced facts stating that having copper finishes reduces HAIs by 58%. Also, copper surfaces are environmentally friendly and completely recyclable. Below are a few facts on why copper surfaces are effective.

- Fixtures and sinks that are produced with antimicrobial copper are safe to use and never wear.

- Copper surfaces deliver continuous and ongoing antibacterial action.

- Antimicrobial copper surfaces also kill more than 99.9% of bacteria within 2 hours.

Antimicrobial Copper Thin Coatings from Cunov are custom made to fit high-touch healthcare surfaces such as bed rails, door handles, cabinet handles, light switches, soap dispensers, and more. The coatings are made of 99.9 percent metallic copper and can be adhered to all hard surfaces, including plastic (rugged or smooth), stainless steel, and melamine.

Research study at Grinnell Regional Medical Center

The results are undeniable. A clinical study investigating the bacteria-killing properties of copper has proven once again that the metal can play a leading role in fighting bacteria1 that cause healthcare-associated infections (HAIs). The paper also reached a second finding destined to shake-up the cleaning practices in the healthcare industry.

Published in the September 28, 2016 online edition of the American Journal of Infection Control and authored by Grinnell College associate professor of biology Shannon Hinsa-Leaure, Ph.D., the study showed that:

- EPA-registered CuVerro® copper kills 99.9% of bacteria it comes in contact with including e. coli and superbugs MRSA and VRE.

- Bacterial loads do not rebound in patient rooms where surfaces are made of copper, whether the room is occupied or not.

- Germs quickly recolonize on surfaces made of stainless, plastic, or wood.

Click here to read the full research study conducted at Grinnell Regional Medical Center in Grinnell, Iowa.

TEXTILES

You might not notice, but when you walk into a hospital or doctor’s office you are surrounded by antimicrobial fabrics. These fabrics were designed and engineered to help inhibit the growth of bacteria. Examples of textiles that are utilized within the space can be found in the clothing that doctors and surgeons wear, bed sheets, pillow coverings, and curtains.

An example of a medical textile and how it’s used is Herculite Inc.’s Sure-Chek™ line of medical fabric products.

1. DESIGNTEX DAPPLE (BEE) This polyester textile is cleanable using water- or solvent-based cleaners, and at a 10:1 dilution of water to bleach.

2. DESIGNTEX HINT (PINKISH) This acrylic-polyester fabric can be cleaned with water-based or solvent cleaners as well as bleach diluted at a 4:1 ratio. Since it can be maintained using standard as well as biodegradable nontoxic cleaners, it does not have any perfluorinated stain-resistant finish.

3. MOMENTUM RUBATO This fabric uses a special yarn made entirely of Repreve solution-dyed recycled nylon. It has no chemical finishes or top coat, yet is bleach cleanable at a 4:1 ratio. Thanks to the nylon backing, it is fully recyclable through Unifi Inc.’s take-back program.

4. DESIGNTEX HINT (CANARY) This acrylic-polyester fabric can be cleaned with water-based or solvent cleaners as well as bleach diluted at a 4:1 ratio.

5. MOMENTUM CROQUET Also part of Momentum’s Rubato collection, this fully recyclable fabric uses the same recycled nylon yarn, and is bleach cleanable despite eschewing chemical finishes and a top coat.

You can find other examples of textiles appropriate for healthcare use by visiting Metropolis Magazine.